Problem: Moving and replacing feedwater heaters in a confined plant setting.

Solution: Barnhart used innovative engineering and air skates to get through plant obstructions.

A great Lakes area nuclear plant in Wisconsin needed to replace four feedwater heaters (FWH) and Barnhart was called in to complete the project. In order to remove the heaters, the team used jacks to raise them from their original anchor bolts and onto the custom fabricated saddles sitting on top of the Barnhart air skates.

The FWH traveled a path toward the crane bay on top of the air skates until it reached an obstruction that one of the heater's nozzles could not clear. To get past it, the heater had to be rotated on its axis and then returned to the original position as planned once the obstruction was cleared.

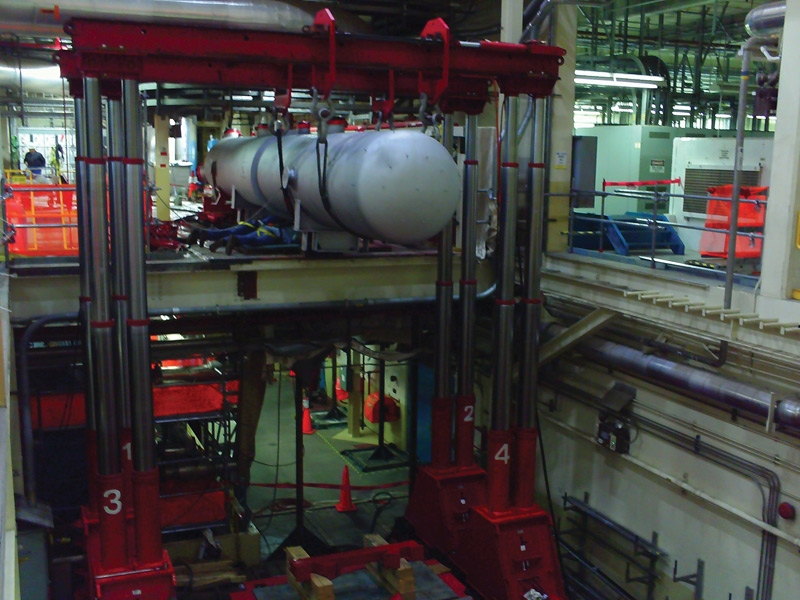

Once at the crane bay, Barnhart used an 800-ton gantry to lower the feed water heaters twenty six feet to the Goldhofer trailer. From there they were transported to a laydown area on site. With a four day delayed start, Barnhart still completed the project ahead of the original scheduled completion date.