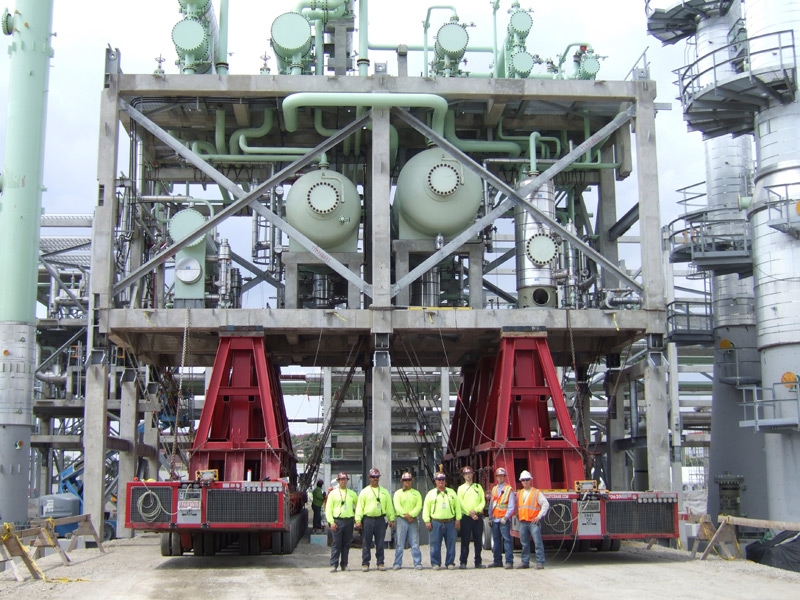

Problem: Barnhart was hired to transport and set more than 90 pieces of equipment weighing from 60,000 to 1,500,000 lbs.

Solution: Barnhart's planning and risk management team were essential in completing the project on time.

Description: Barnhart was hired to provide engineering, project management, supervision, craft and equipment to transport and set more than 90 pieces of equipment weighing from 60,000 to 1,500,000 lbs. for a refinery in Michigan.

Phase One - Barnhart provided a 260' by 72' wide heavy deck barge and tugs to receive 11 vessels from ship's gear at Nicholson Dock on the Detroit River.

Phase Two - Barnhart secured and rolled off 12 barge loads of 51 heavy process and pipe modules in addition to the 11 vessels. Barge receipt and offloading was staggered over five months and repeated for the 12 barge loads - blocking the river each load.

Phases Three and Four - Barnhart added 32 additional vessels to the original contract that called for staging, transporting and setting 60 pieces of equipment. Phase four hauls required extensive coordination with city departments and utilities. Specific equipment had to be hauled on specific dates, complicating coordination. Barnhart met every haul date.

Phase Five - During the heavy lift portion of the project, the team mobilized 330-ton, 600-ton, and 825-ton crawler cranes to set vessels and modules. Barnhart's versatile Modular Lift Tower and 850- ton Strand Jack were used to set the largest vessel - the 750-ton reactor.

Barnhart provided a 260' by 72' wide heavy deck barge and tugs to receive 11 vessels from ship's gear at Nicholson Dock on the Detroit River.

Barnhart secured and rolled off 12 barge loads of 51 heavy process and pipe modules in addition to the 11 vessels. Barge receipt and offloading was staggered over five months and repeated for the 12 barge loads - blocking the river each load. Barnhart added 32 additional vessels to the original contract that called for staging, transporting and setting 60 pieces of equipment. Phase four hauls required extensive coordination with city departments and utilities. Specific equipment had to be hauled on specific dates, complicating coordination. Barnhart met every haul date.

During the heavy lift portion of the project, the team mobilized 330-ton, 600-ton, and 825-ton crawler cranes to set vessels and modules. Barnhart's versatile Modular Lift Tower and 850- ton Strand Jack were used to set the largest vessel - the 750-ton reactor.