Blade Bar Revolutionizing Wind Projects

You wouldn’t expect a crane company to devise a system for wind maintenance projects that requires fewer cranes, but that’s what we’ve done with our custom designed blade bar.

The blade bar replaces the industry standard two crane method for wind turbine blade removal, requiring only one crane. One less crane means less mobilization, labor, truck and equipment costs for our customers. Reduced crew and crane operations also mean a safer process.

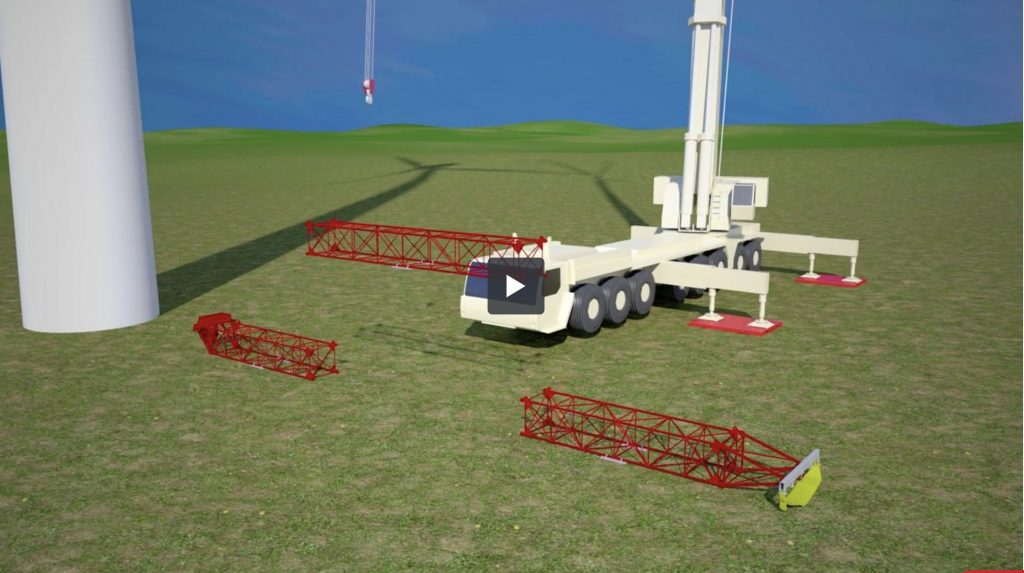

The blade bar is a metal frame, adjustable in five-foot increments from 5’ long to 115’ long, making it fully adjustable to the blade’s specs. The length of the bar is adjusted on the ground and a sling is attached at one end. The blade is then lifted by a single hydraulic or crawler crane to the height of the damaged blade, eliminating a critical lift with a standard single crane operation.

At the end of the bar is a custom counterweight system, which easily adjusts to meet the blade’s center of gravity. A hydraulically powered unit can rotate the bar and blade on three different rotation points in either direction.

The sling at the end of the bar is threaded over the damaged blade and another sling is eventually attached at the root end, which stabilizes and balances the blade. Once the blade is safely secured, it is disconnected from the turbine’s hub and the blade bar and blade are lowered to the ground.

Among the blade bar’s further advantages is that one crane operator is in control of all operations versus two to coordinate. Smaller crane pad requirements also mean less environmental risk. The blade bar system is also able to handle higher wind speed operating limits.

See the blade bar in action in this animation.