Safe, Reliable, and Cost-Effective: the Modular Lift Tower, Part III

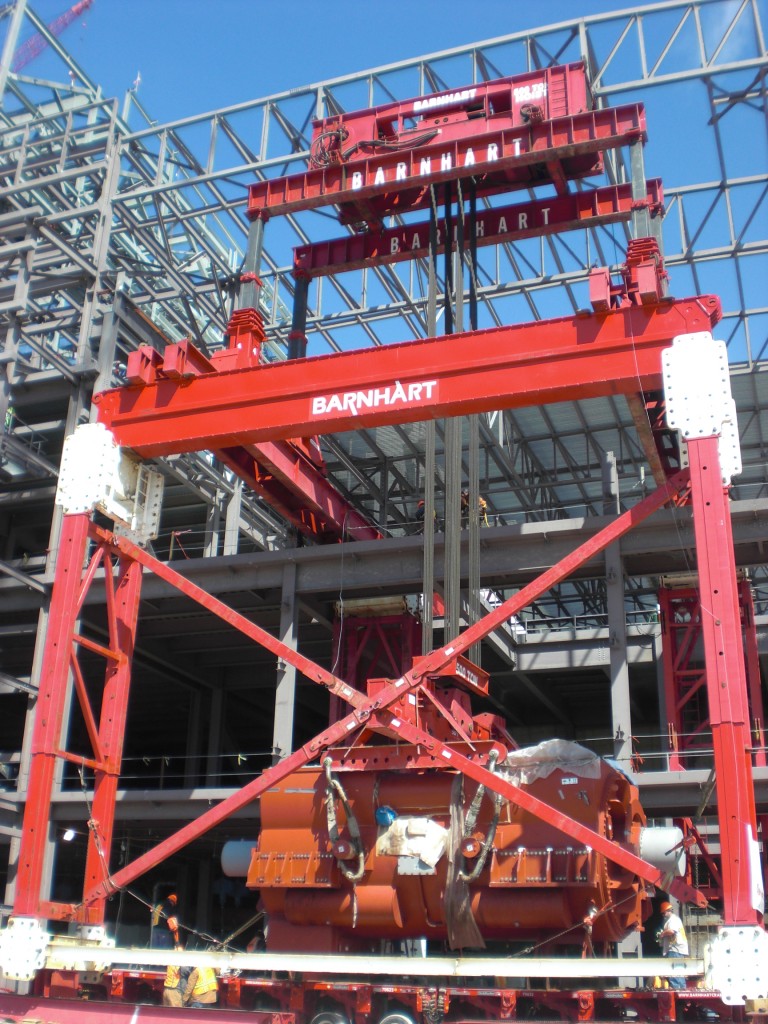

In the two previous articles (Part I and Part II), we demonstrated the growing need for a lifting device that rivaled cumbersome heavy lift cranes. Barnhart’s engineers solved this problem by creating the highly versatile Modular Lift Tower (MLT).

While this machine is highly effective in major lifts, its design is also intrinsically safe. Barnhart engineers, as always, made safety a priority from developing the concept of the tower to every lift it makes. The latest in computer modeling, frequent tests, and third party reviews have simply proved the MLT’s reliability and safety.

When using the innovative lifting machine, skilled Barnhart crews carefully erect the tower on site. Only qualified employees familiar with the erection of the MLT work on the project. Pin connected mobile joints, adjustable height sections, and adjustable bracing make the equipment safe and user-friendly.

In addition, all personnel on the MLT are securely tied off to the bracing at all times, and assemblers construct integral ladders on bents and nodes. Crews employ retractable lifelines at every level, and sliding beams at horizontal catwalks allow employees to walk back-and-forth between vertical bents.

On the top of the tower, platforms surround five-feet girders and lifting equipment to further enhance labor safety. The tower also uses mandatory FAA hazard lighting systems.

The folks operating the equipment know absolutely everything there is to know about the MLT. There’s virtually nothing that will surprise the Barnhart team, and less surprises means higher safety and efficiency. They simply designed it with all this in mind.

But that’s not all they we’re thinking.

The sheer weight of heavy lift cranes and their massive counterweights can skyrocket transport costs, especially when hauled over long distances. For example, a 1,300-ton heavy lift crane may require 100 tractor trailer loads for transport, while the MLT would require only 16, saving a customer up to 25% in costs.

To further reduce costs, the modules of the towers ship in standard sized national and international freight containers, and as a result, increasing transport efficiency as well. As explained in Part II, this becomes significantly more important when customers need Barnhart to perform heavy lifts at remote sites.

As exhibited above, the Barnhart Modular Lift Tower provides a safe, reliable, and cost effective alternate to heavy lift cranes. And as the two previous articles proved, the MLT provides a much more versatile and portable solution to the growing need for heavier and heavier lifts in smaller and smaller spaces.

To learn more about the modular lift tower, take a look at its specifications on the equipment page.