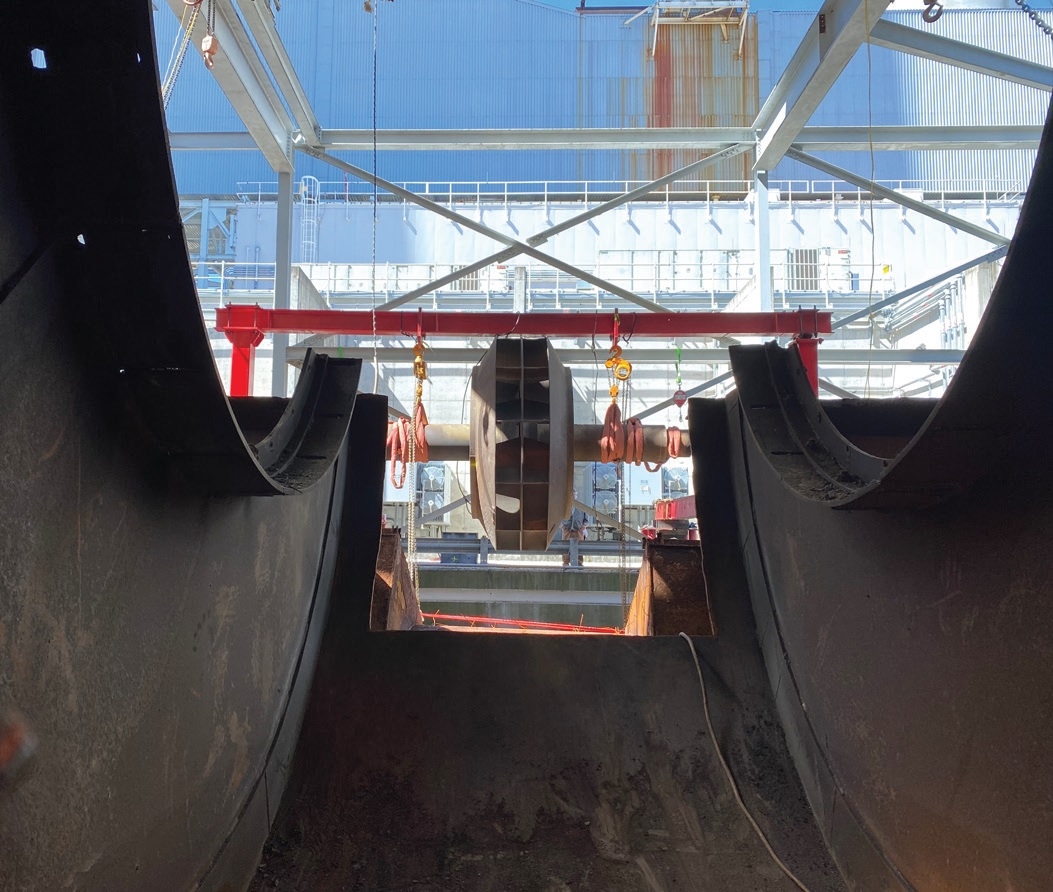

Barnhart was hired to remove and replace a fan rotor at a power plant in Tennessee. Challenges included overhead obstructions and a 60’ wide plant piping trench that had to be spanned. The team assembled a 16” slide system combined with custom fixed gantries.

A beam was placed atop the gantries and two hoists and slings were attached to the rotor shaft. Barnhart’s rigging solution provided a method for removal and replacement of the rotor with minimum requirement of overhead duct removal.

The fan rotor was then slid out of its housing approximately 50’ to an opening in the steel structure above. The crew then lifted the rotor from the system with a 275-ton hydraulic all terrain crane.

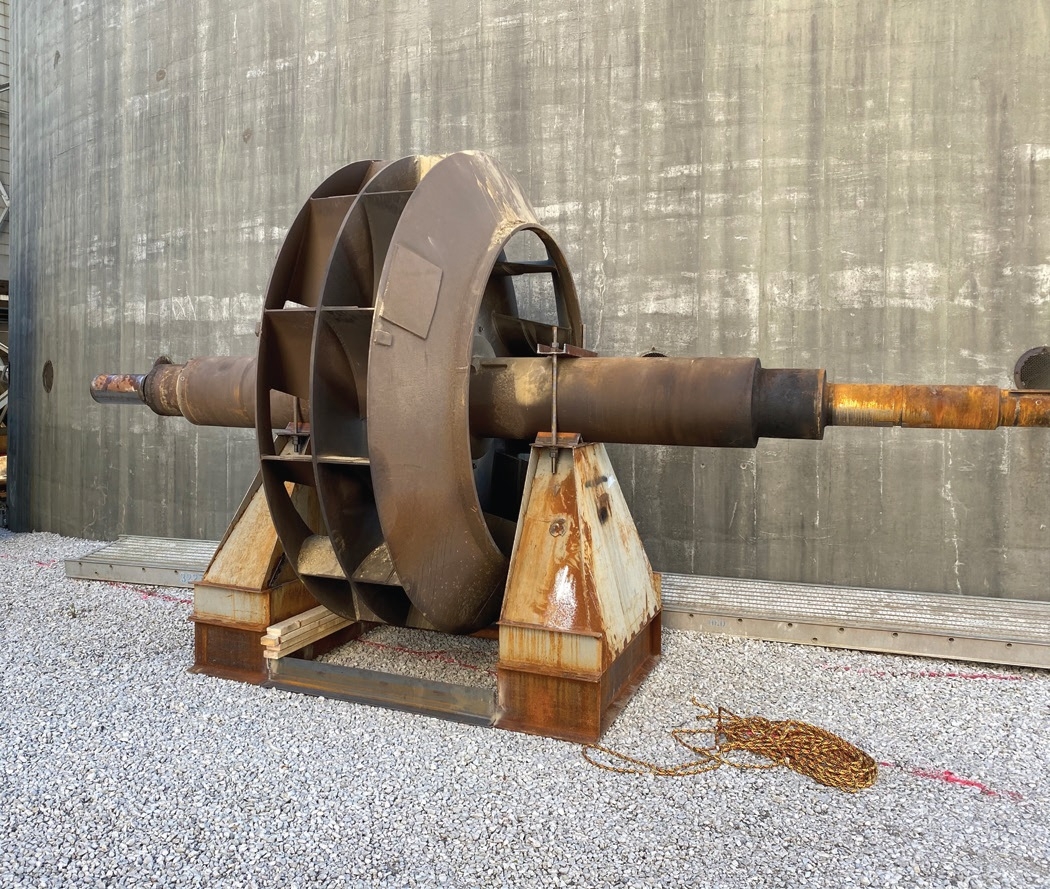

The crane set the rotor on a shipping stand and then the crew reversed the process for the new rotor replacement.